XINNUO ROLL FORMING MACHINE CO., LTD., founded in the 1995s, is a leading manufacturer of sandwich panel production lines in China. With over 30 years of experience in industrial equipment design and manufacturing, we specialize in research, development, and turnkey solutions for sandwich panel production. Our products are exported worldwide and serve a diverse range of construction and industrial markets.

We are committed to providing our customers with efficient, reliable, energy-saving, and customizable sandwich panel production lines that meet various production demands. Our core advantages include:

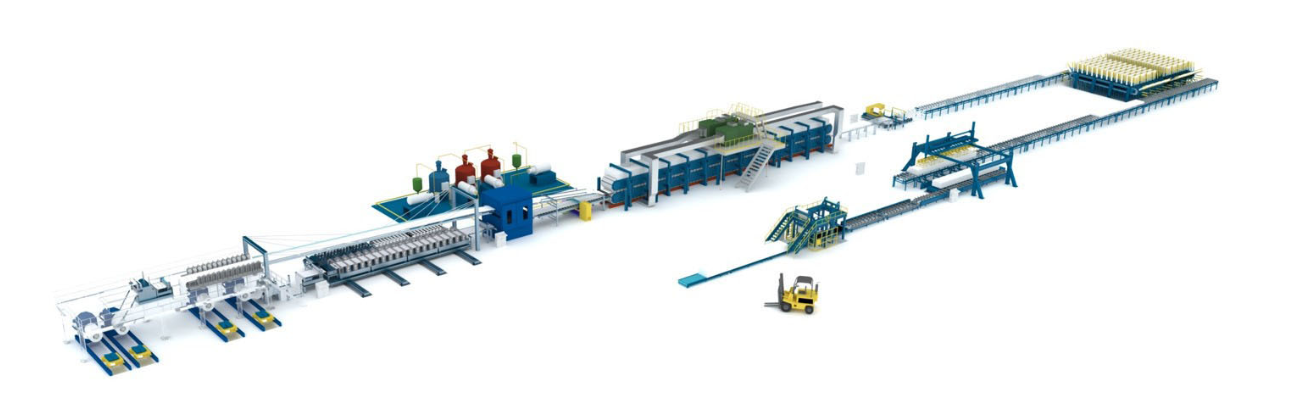

Rock Wool & Foam Integrated Sandwich Panel Line: Supports both rock wool and EPS/XPS foam cores, offering flexible production for diverse building and industrial applications.

EPS Sandwich Panel Line: Uses polystyrene foam (EPS) as core material; high efficiency, stable structure, ideal for economical and large-scale production.

Rock Wool Sandwich Panel Line: Outstanding fireproof and corrosion-resistant performance; suitable for industrial facilities, warehouses, and high-safety construction projects.

Polyurethane (PU) Sandwich Panel Line: Excellent thermal insulation, high panel flatness; widely used in cold storage, industrial buildings, and premium residential projects.

PU Edge-Sealing Sandwich Panel Line: Designed for rock wool or EPS cores, with PU foaming on both sides; panels are tightly sealed, visually appealing, and highly durable.

Z-Lock Sandwich Panel Line: Features a Z-shaped lock-edge structure, compatible with multiple core materials; ensures high panel connection strength and excellent anti-leakage performance.

Semi-Automatic PU Sandwich Panel Line: Flexible customization for production capacity and automation level, suitable for different factory layouts and investment budgets.

We emphasize domestically developed and manufactured equipment, offering performance comparable to imported machinery while significantly reducing procurement costs, delivering excellent value to our clients.

Customized production lines from fully automatic to semi-automatic, single-core to composite-core designs.

Design tailored to factory layout, production capacity, and material requirements.

Equipment upgrade, retrofit, and expansion services for maximizing long-term investment value.

Key components made from premium domestic materials ensure stable and long-term operation.

Each production line undergoes rigorous testing and trial runs, ensuring precise panel dimensions and smooth surface quality.

Complete after-sales system, including 1-year free warranty and lifetime online technical support.

Our products have been exported to Europe, South America, Southeast Asia, the Middle East, and other regions. We provide full-service support for overseas clients, including design, manufacturing, installation, commissioning, and operator training, helping customers achieve fast production and maximize ROI.

At XINNUO, we focus on technological innovation, reliable quality, and professional service. We are committed to advancing the sandwich panel production industry and look forward to partnering with global clients to create a more efficient, sustainable, and intelligent future in building materials manufacturing.